Cookie-Einstellungen

Diese Website verwendet Cookies.

Die für den Betrieb der Website notwendigen Cookies (z.B. Standort- und Sprachauswahl) müssen sie akzeptieren, sonst können sie diesen Webservice nicht nutzen!

Bei allen anderen Cookiearten haben sie die Möglichkeit des Nichtauswählens.

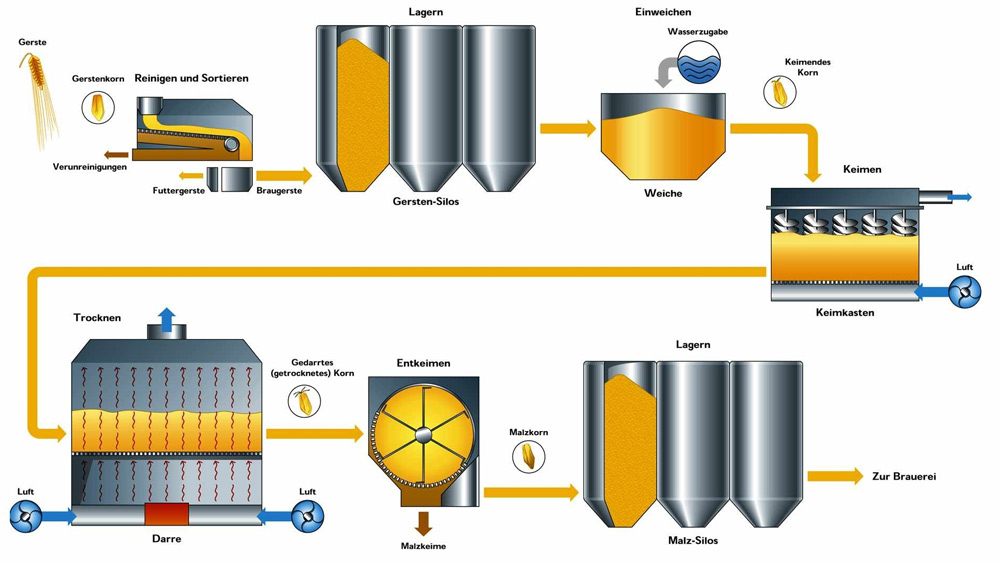

Die Mälzung

Die aktuelle Kapazität ist auf die Verarbeitung von

50.000 Tonnen im Jahr ausgelegt. Die Gesamtkapazität im Silo- und Verladebereich von 36.000 Tonnen ermöglicht die rationelle Verarbeitung einheitlicher Partien. Pro Stunde

können 150 Tonnen Gerste oder Weizen angenommen werden. Sechs Weichbehälter mit einem

Fassungsvermögen von je 45 Tonnen bestimmen die

erste Produktionsstufe, gefolgt von sechs Keimkästen

mit einer Kapazität von je 135 Tonnen.

Analysedaten aus der Produktion und Sollwerte der von unseren Kunden gewünschten Malzsorten lassen sich mit einer rechnergestützten Anlage optimieren. Die Strom- und Wärmeversorgung erfolgt über ein erdgasbetriebenes Blockheizkraftwerk, sowie nachhaltig in einem Waldhackschnitzel-Heizwerk.